260t Concrete Railway Bridge Beam Launcher Machine Beam Erection Crane for Install

260t concrete railway bridge beam launcher machine beam erection crane for install Bridge girder erection machine merges

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | BGEM |

| Type | Ordinary |

| Cart Transverse Moving Speed (M/Min) | 2.45 |

| Cart Longitudinal Moving Speed (M/Min) | 4.25 |

| Speed of Bridge Transport Vehicle (M/Min | 8.5 |

| Return Speed (M/Min) | 17 |

| Transportation Capacity (T) | 100*2 |

| Applicable Skew Bridge Angle | 0-450 |

| Tolley Longitudinal Moving Speed (M/Min) | 4.25 |

| Trolley Lifting Speed (M/Min) | 0.8 |

| Applicable Span (M) | ≤55 |

| Lifting Capacity (T) | 200ton |

| Transport Package | Container Loading for Better Cost Saving |

| Specification | 40′HQ or bulk cargo ship |

| Trademark | Nucrane |

| Origin | Henan Changyuan City |

| Production Capacity | 100sets/Month |

Product Description

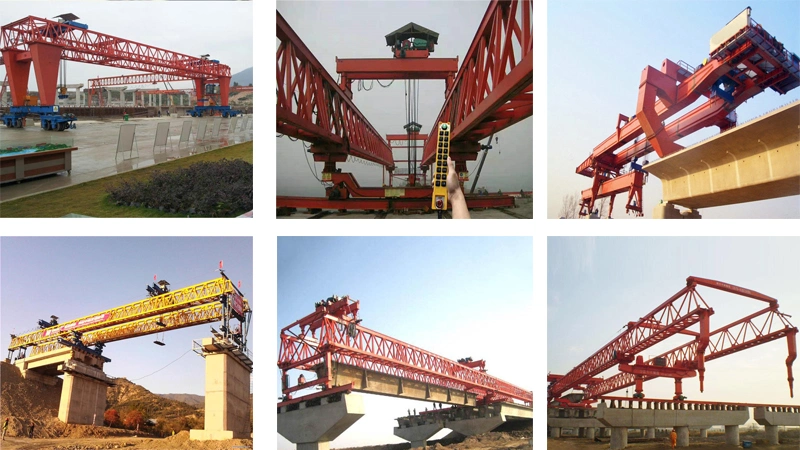

260t concrete railway bridge beam launcher machine beam erection crane for install

Bridge girder erection machine merges an adaptation of a wide range of work, excellent performance, convenient operation, safety structure into a single whole. It has the steel structure of rail type precast beam hoisting rack equipment. This product can be used not only in plain construction, but also to meet the construction of mountain highway slope, small radius curved bridge, skew bridge and tunnel bridge requirements.

The bridge girder erection machine consists of main girder, crane, front legs, rear legs, front leg cylinder, rear leg cylinder and the transverse connection of front, middle, rear legs. The control part is composed of hydraulic system and electric control system. The bridge girder erection machine is characterized by reasonable compact structure and convenient installation, the main standard girder is connected by pin connection. The double girder structure is connected between the two frame girders by welded pipe.

The bridge girder erection machine not only can meet the standard set up, but also it can meet the cross curve erection, variable span erection, span continuous beam, composite beam, continuous steel etc. In addition to bridge erection, simply supported girder erection and point lifting, it is characterized by good stability, high efficiency, safety and reliability, variable span convenient adjustment and convenient operation and etc.

Technical parameters of girder Launcher crane:

| model | BGEM50/200 | BGEM 40/160 | BGEM 40/160 | BGEM 35/100 | BGEM 30/100 |

| Lifting capacity (t) | 200 | 160 | 120 | 100 | 100 |

| applicable span (m) | ≤55 | ≤50 | ≤40 | ≤35 | ≤30 |

| applicable skew bridge angle | 0-450 | 0-450 | 0-450 | 0-450 | 0-450 |

| trolley lifting speed (m/min) | 0.8 | 0.8 | 0.8 | 1.27 | 0.8 |

| tolley longitudinal moving speed (m/min) | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 |

| cart longitudinal moving speed (m/min) | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 |

| cart transverse moving speed (m/min) | 2.45 | 2.45 | 2.45 | 2.45 | 2.45 |

| transportation capacity (t) | 100X2 | 80 X2 | 60X2 | 50X2 | 50X2 |

| speed of bridge transport vehicle (m/min) | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 |

| return speed (m/min) | 17 | 17 | 17 | 17 | 17 |

Safety Features

Safety is the most important issue for cranes.To ensure the safety,the following safety devices are equipped in BL crane.Crane traveling limit switch. Overload protection device. Lifting height limit device. Voltage lower protection function . Phase sequence protection function. Emergency stop function. Rain cover for outside hoist, driving units, electric cubicle. Warining indicator : flashing nights and warning sounds. Wire-less infra-detector for anti-collusion.

| Packing/Delivery Adevices: | |

| 1 | Crane Beam & Main Equipment: Packaged by color strip woven plastic cloth for abrasion reduce andmoisture-proof. |

| 2 | Crane Kit & Electric Accessories: Export standard high quality plywood case for reduce distortion. |

| 3 | Loading & Delivery Option: Prefered to choose container loading for better cost saving. Oversize beams and equipment can be cut for container loading as suitable size crane products. Bulk cargo shipment will beused when container loading not available. |

| 4 | Loading Port: Qingdao Port is prefered, Tianjin Port, Shanghai Port etc. available on your demand. |

| 5 | Delivery Time: Lead time 30-45days, port time 5 days, estimate time of arraival (ETA) to Xxxxxx Port 35-50 working days. |

FAQ1. What's the information should I provide when inquiry about the bridge launching tube beam launcher crane?a.we need the Bridge Drawing, the Maximum longitudinal slope and the Maximum Transverse slope.b.The Girder/beam drawing.2. How many Personnel and equipment to assemble launching gantry in the worksite we need?Personnel: 8 to 10 workers equipmentTruck crane > 50 t : 2 setsΦ19.5 steel wire rope 8 m: 4 ropesSleepers: severalElectric welding machine: 1 setOxygen, acetylene: 1 setHammer(12 pound and 8 pound): 1 set for eachWrench and pincher: several Gradienter: 1 set3. What are inspection standard for load test of bridge launching tube beam launcher crane?Dynamic load test: 1.1 times rated load.Static load test: 1.25 times rated load.4. How to make highway bridge concrete girders?Highway Bridge concrete girders could be made by 4 methods:a. Full span prefabrication.b. Segment girder prefabrication.c. Full span cast-in-place girder.d. Segment cast-in-situ.5. How about maintenance of bridge launching tube beam launcher crane?a. Lubricating:Working performance and service life of all mechanisms of crane depend on lubricating to a big extent.b. Steel wire rope:Fracture of wire has to be specially noticed. A new steel wire rope has to be changed immediately with the condition of broken wire, broken strands and wear loss to scrapping standard.c. Spreader: The spreader has to be checked regularly.d. Pulley block:Mainly check rope race wearing condition, check whether wheel flange is cracked and whether pulley could get stuck in the axle or not.e. Wheels:Regularly check wheel flange and tread, a new wheel has to be immediately replaced as crack part or wearing in wheel flange reaches 10% of wheel thickness;Re-polishing has to be done as diameters between two driving wheels on tread differs more than D/600, or there are severe scar on the tread.f. Brake: Check one time per shift; The brake should be in accurate movement, and pins do not allow to be stuck. Brake shoes shall fit brake wheels correctly; the brake shoes interval shall be equal to open them.